Production Overview

Aluminum Extrusion

Process

& Stretching

-

1

Billet Preheating

Work Description

Work DescriptionFor optimal extrusion results, billets must be preheated to ensure that the extrusion exit temperature remains within the alloy’s solution heat treatment range (e.g., 515–535℃ for alloy 6063). Proper control of preheating temperatures according to alloy type and product geometry ensures excellent surface finish, consistent mechanical strength, and uniform anodized color.

Operating Conditions6063 Alloy Billets

- Solid : 460–480℃

- Hollow : 470–480℃

6061 Alloy Billets

- Solid : 470–490℃

- Hollow : 480–500℃

-

2

Die Loading

Work Description

Work DescriptionTo ensure stable extrusion, dies are preheated to maintain the proper bearing section temperature as the billet passes through. Preheating conditions vary depending on alloy type, product geometry, and die size.

Operating ConditionsTypical Preheating Conditions (6063 Alloy)

- Solid : 410–440℃

- Hollow : 410–450℃

Preheating Duration by Die Size

- 9” → Minimum 5 hours

- 7” → Minimum 3 hours

- 6” → Minimum 2 hours

-

3

Extrusion

Work Description

Work DescriptionIn the extrusion process, billet length and processing parameters are carefully optimized by considering profile characteristics, extrusion ratio, run-out table length, and press capacity. This ensures stable production and consistent quality.

Operating ConditionsMaximum working weight/length by inch size:

- 9” Press: Max. 9.5 kg/m, Min. 6.5 m length

- 7” Press: Max. 3.5 kg/m, Min. 6.5 m length

- 6” Press: Max. 1.5 kg/m, Min. 7 m length

Extrusion Ratio = Container cross-sectional area ÷ Die bearing cross-sectional area

-

4

Cooling

Work Description

Work DescriptionProper cooling is critical to maintaining the quality of extruded products. If cooling is insufficient, it can lead to reduced tensile strength and elongation after heat treatment, as well as surface defects such as inconsistent anodizing or coloring.

Operating ConditionsTypical Cooling Rates (to 250℃ after extrusion)

- 6063 Alloy: 1.58℃/sec (95℃/min)

- 6N01 Alloy: 3℃/sec (180℃/min)

- 6061 Alloy: 10℃/sec (600℃/min)

-

5

Straightening & Stretching

Work Description

Work DescriptionTo enhance mechanical strength and maintain dimensional straightness, extruded profiles undergo a straightening process. Typically, profiles are stretched by about 0.5% of their length. Stretching beyond 2% may result in defects such as orange peel and dimensional inconsistencies.

Operating ConditionsMinimum straightening lengths

- 9” : 10M

- 7” : 10M

- 7” : 3M

- 6” : 10M

-

6

Cutting

Work Description

Work DescriptionExtruded profiles are cut to the required product length. Clamp marks from the stretcher and joint overlaps at both ends are removed as scrap to ensure product quality.

Operating ConditionsMaximum / Minimum cutting lengths

- 9” : 3M / 13M

- 7” : 3M / 7M

- 7” : 3M / 8M

- 6” : 3M / 7M

-

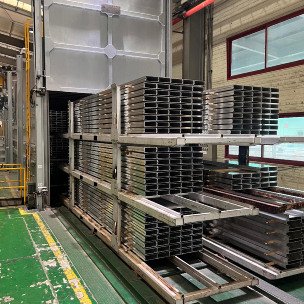

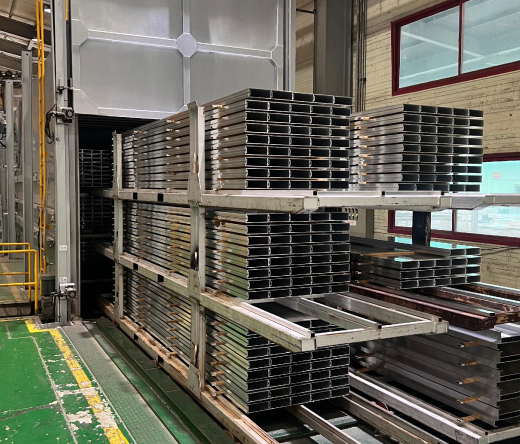

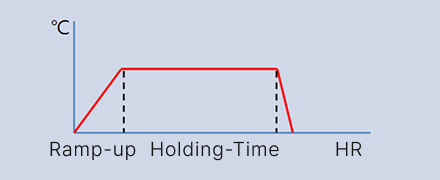

7

Aging

Work Description

Work DescriptionTo ensure the required mechanical properties, extruded profiles undergo an aging process. This involves controlled heating cycles defined by ramp-up time, ramp-up temperature, holding time, and holding temperature. Specific aging conditions vary according to the profile type and application.

Operating Conditions

Aging Conditions

- 195℃ - 4HR

- 175℃ - 9.5HR

- 175℃ - 13.5HR

-

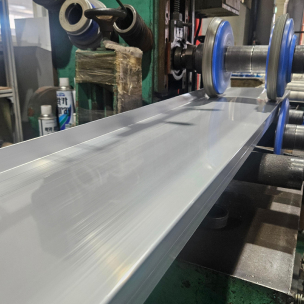

8

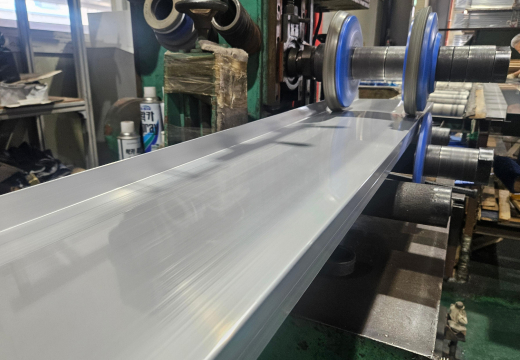

Rolling

Work Description

Work DescriptionFor extruded profiles requiring corrections that cannot be fully achieved by die design, rolling is applied either before or after heat treatment. This finishing process is primarily used on products over 250 mm in width to ensure proper squareness and flatness.

Operating ConditionsAfter heat treatment, products can only undergo basic rolling adjustments.

If secondary deformation occurs from changes in the aluminum microstructure, corrective processing is carried out.